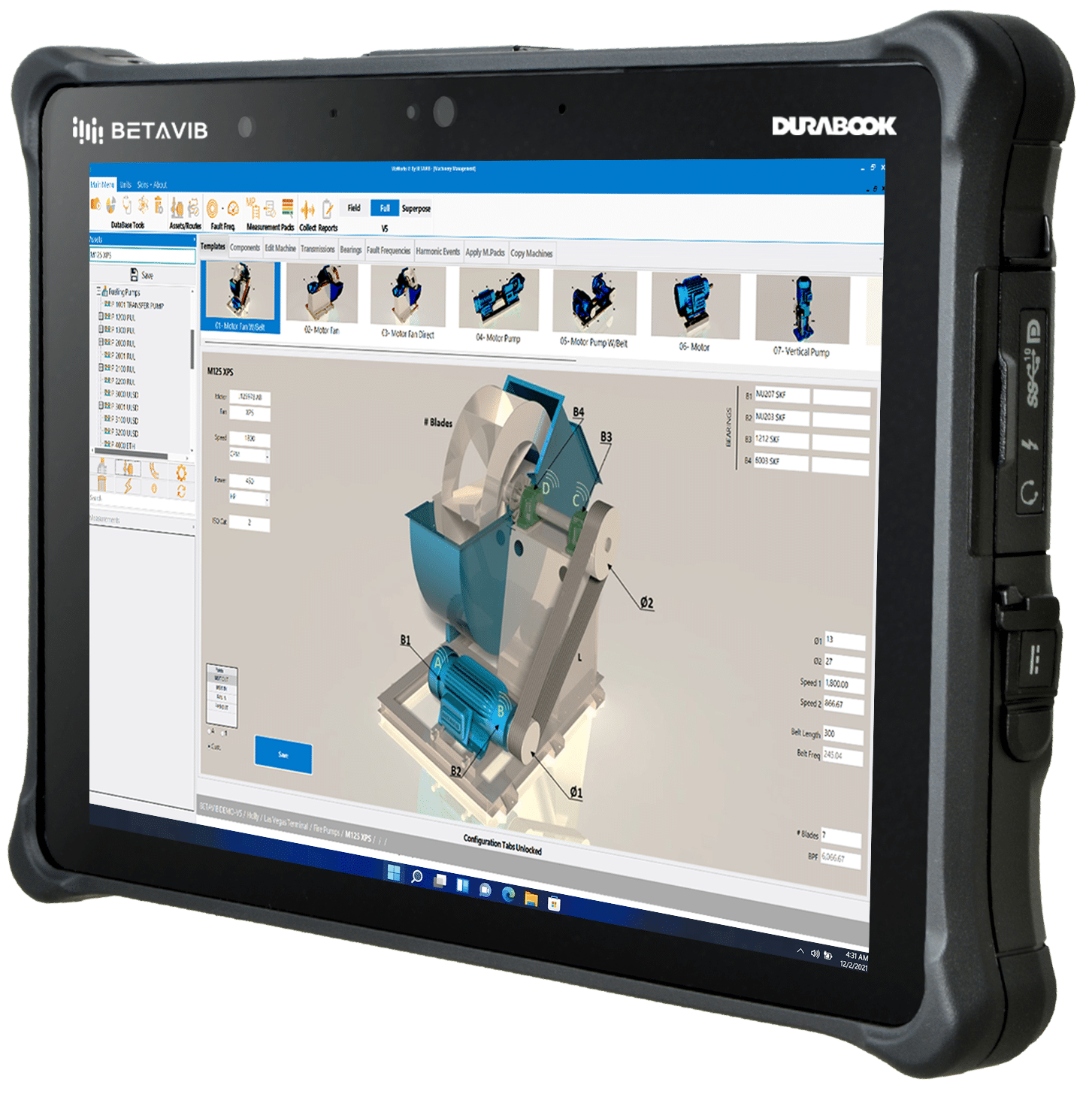

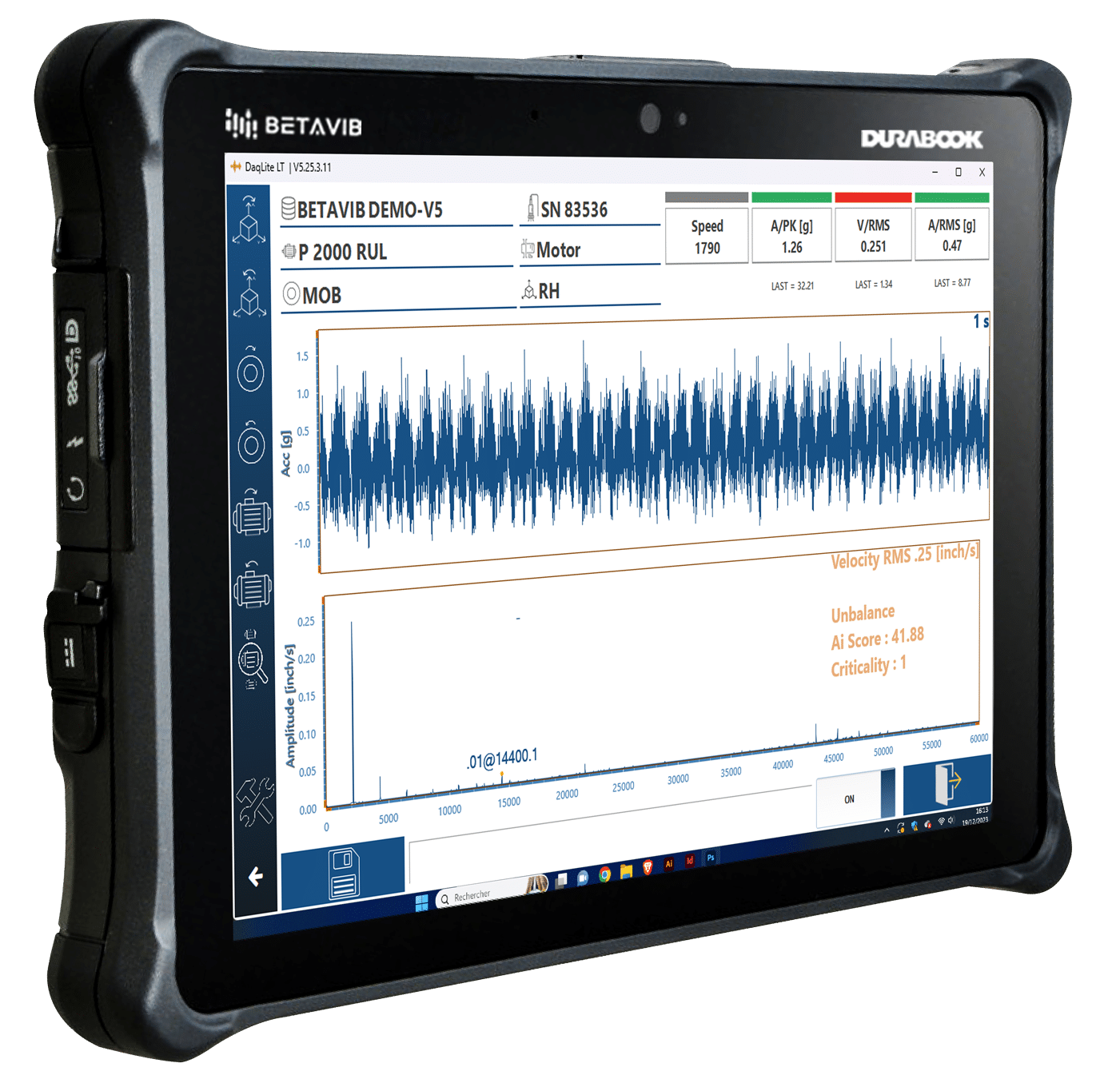

In condition monitoring, capturing real-time data from machinery sensors like vibration, temperature, and pressure is essential, whether through portable collectors or online solutions. At BETAVIB, we recognize the importance of having the right tool, which is why our user-friendly interface and superior data collection capabilities set us apart. Our technology ensures quick, accurate capture of critical vibration metrics, from overall measurements to detailed power and narrow band spectrums, empowering informed decisions for operational excellence.

BETAVIB’s latest innovation, VibWorks LT, is a cost-effective, portable solution designed for seamless integration within the VibWorks environment. This advanced tool offers high-quality data acquisition, providing efficiency and flexibility without compromising your budget. With the ability to sync data to the Cloud, VibWorks LT ensures easy access to BETAVIB’s UHDM analysis platform, where users can gain valuable insights such as maintenance schedules and equipment adjustments.

No products in the cart.