TAKE THE

RIGHT DECISION

USING THE RIGHT TOOL

WELCOME TO OUR VIBWORKS SUIT

Overview

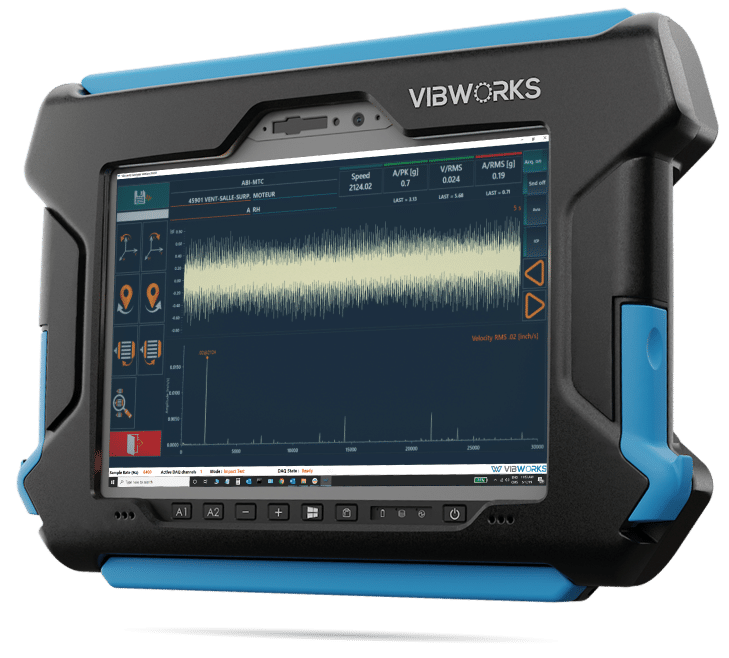

In condition monitoring, capturing real-time data from machinery sensors like vibration, temperature, and pressure is essential, whether through portable collectors or online solutions. At BETAVIB, we recognize the importance of having the right tool, which is why our user-friendly interface and superior data collection capabilities set us apart. Our technology ensures quick, accurate capture of critical vibration metrics, from overall measurements to detailed power and narrow band spectrums, empowering informed decisions for operational excellence.

1

%

START UP COST

Save more than 82%art-up Costs, thanks to our quick delpoy took.

1

%

EFFICIENCY

U.HD.M workstation is 75% more efficient than conventional HD analysis methods.

1

%

SPEED

Vibworks collector is 77% faster than all conventional collectors on the market.

Features To Discover

Advanced Processing

Overall's, Spectrums, Envelop and demodulations, Hilbert, Spectrograms, Kurtogram.

Realtime Audio

Wireless Audio from sensor with Industrial Noise canceling headset.

Long Twf Technology

1st Collector on the Market based 100% on TWF.

Embedded Features

Realtime FFT Analyzer with velocity, acceleration spectrums, and color-coded indicators.

Simultaneous Triax

Simultaneous single and triax acquisition during route.

Embedded Camera

Capture asset photos directly to DB and generate reports.

WHAT YOU GET WITH OUR VIBWORKS

Our Vibworks system is available in three configurations, combining both hardware and software to meet diverse operational needs. The hardware includes our high-performance collector, which is equipped with essential features such as a camera, audio capabilities, and four input channels for comprehensive data acquisition. On the software side, we offer three distinct strategies, starting with Vibworks Knight. This basic workstation is designed for essential condition monitoring and includes key features:

- 1 Channel Instrument

- Smart Machines creation

- Extended Bearing DB

- Standard Reports generation

- Basic and advanced signal processing tools

- Long time waveform collector

- Automated fault frequencies management

- Automated transmission management

The Rook Strategy enhances the Knight Strategy with additional features for more comprehensive monitoring :

- 3 Channel Instrument

- Smart Machines creation

- Extended Bearing DB

- Standard Reports generation

- Basic and advanced signal processing tools

- Long time waveform collector

- Automated fault frequencies management

- Automated transmission management

- Anomalies reports generation

- Automated DB definition

- S.A.M : Smart Alarm Module

- History Reprocessing

- Advanced Reporting Capabilities

The King Strategy, our best-selling solution, builds on the Rook Strategy with additional advanced features for optimal machine monitoring. In addition to the capabilities of the Rook, such as Anomalies Report Generation and the S.A.M (Smart Alarms Module), the King Strategy introduces Ultra HD Monitoring (4k analysis) for highly detailed, precise data. It also features an Interactive Color-Coded Dashboard, providing users with an intuitive and visually engaging overview of machine health. Furthermore, the King Strategy offers direct Bluetooth audio from sensors, enabling real-time audio feedback for enhanced diagnostics and faster decision-making.

- 3 Channel Instrument

- Smart Machines creation

- Extended Bearing DB

- Standard Reports generation

- Basic and advanced signal processing tools

- Long time waveform collector

- Automated fault frequencies management

- Automated transmission management

- Anomalies reports generation

- Automated DB definition

- S.A.M : Smart Alarm Module

- History Reprocessing

- Advanced Reporting Capabilities

- U.H.D.M Ultra HD Monitoring

- Interactive Color coded DashBoard

- Direct Bluetooth audio from sensor

Our Data Acquisition Module (DAQ LITE)

The VibWorks Balancer can save shaft sensitivity coefficients for future use, eliminating trial runs in subsequent balancing tasks. It provides ISO 1940-compliant normalized balancing, automatic suggestions for trial weights, and detailed reports in PDF, DOC, and HTML formats. Proximity probes enhance precision for low-speed machinery, while advanced cross-correlation algorithms ensure optimal phase stability, minimizing risks like wear, increased costs, and safety hazards.

Easier Visualization

Real-time overall indicators with color-coded tanks, highlighting alarm conditions for easier monitoring.

Advanced Analysis

Ability to conduct real-time analysis on raw sensor data for deeper insights.

Higher Accuracy

Real-time waveform display with customizable velocity and acceleration spectra for precise measurements.

Cart