TAKE THE

RIGHT DECISION

USING THE RIGHT TOOL

Overview

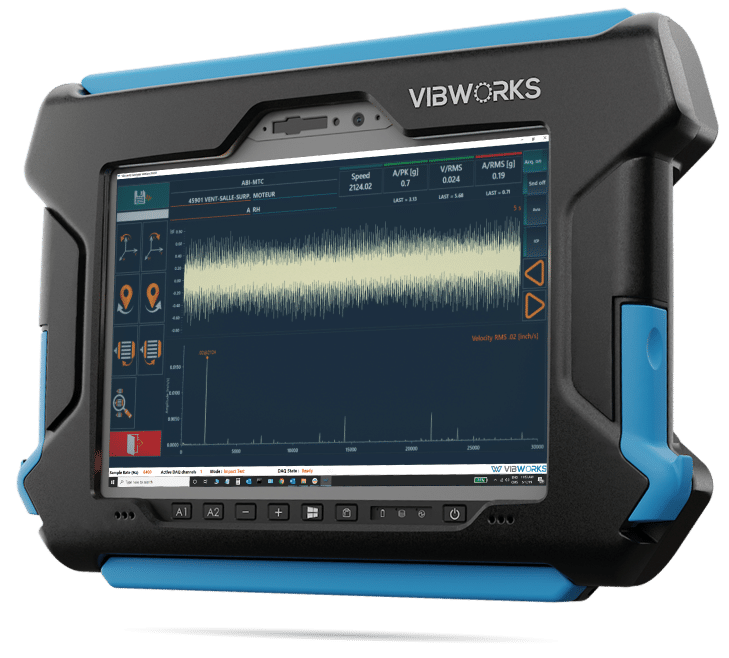

The VibWorks Balancer is a user-friendly add-on module to the BETAVIB Suite, optimized for both simplicity and efficiency. Built on the same hardware platform as the VibWorks Collector and Analyzer, it enables users to perform balancing tasks swiftly through a streamlined, yet powerful interface. With up to four physical channels, the system accelerates balancing operations by allowing simultaneous data acquisition, ensuring faster and more precise results. Furthermore, VibWorks Balancer includes real-time phase stability monitoring, displayed on dynamic polar graphs, to ensure optimal balancing conditions throughout the entire process.

Features To Discover

Real-Time Vibration Spectrum Analysis

Continuously displays vibration spectra, enabling monitoring of amplitude, phase, and critical frequency components for comprehensive diagnostic insights during balancing.

Dynamic Vector & Phase Visualization

Provides real-time tracking of phase stability and dynamic vectors on polar plots, ensuring precise identification of unbalance and corrective measures.

Single-Shot Balancing

Performs shaft sensitivity analysis through a single trial run, streamlining the process for future corrections.

Flexible Units & Measurement Settings

Allows users to select preferred measurement units (g, kg, mm/s, IPS, RMS, CPM, Hz) for vibration, weight, and radius, facilitating seamless integration with industry-standard workflows.

Advanced Polar Diagram Feedback

Real-time polar plots enhance balancing precision by visually confirming the relationship between unbalance vectors, corrective weights, and phase adjustments.

ISO 1940 Compliance

Automatically verifies balancing operations against ISO 1940 standards, ensuring permissible residual unbalance and compliance with industrial quality benchmarks.

Vibworks Balancer Gen 5.0

The VibWorks Balancer can save shaft sensitivity coefficients for future use, eliminating trial runs in subsequent balancing tasks. It provides ISO 1940-compliant normalized balancing, automatic suggestions for trial weights, and detailed reports in PDF, DOC, and HTML formats. Proximity probes enhance precision for low-speed machinery, while advanced cross-correlation algorithms ensure optimal phase stability, minimizing risks like wear, increased costs, and safety hazards.

Vibworks Balancer Gen 5.0

The BETAVIB VibWorks Balancer Software is engineered to deliver unparalleled accuracy and efficiency, offering a comprehensive suite of features to meet the most demanding rotor balancing requirements. Designed with both technical sophistication and user-friendly functionality, it is an indispensable tool for professionals seeking precision and control in balancing operations.

Report

Reports are generated with a single click and are fully customizable with your logo, contact details, and machine images, ready for printing.

Vibworks Balancer Gen 5.0

The VibWorks Balancer can save shaft sensitivity coefficients for future use, eliminating trial runs in subsequent balancing tasks. It provides ISO 1940-compliant normalized balancing, automatic suggestions for trial weights, and detailed reports in PDF, DOC, and HTML formats. Proximity probes enhance precision for low-speed machinery, while advanced cross-correlation algorithms ensure optimal phase stability, minimizing risks like wear, increased costs, and safety hazards.

Setup

Units can be easily selected orchanged with a mouse click. Balance correction is achieved in one or two planes, and tachometers and sensors are positioned graphically for simplicity.

Vibworks Balancer Gen 5.0

The VibWorks Balancer can save shaft sensitivity coefficients for future use, eliminating trial runs in subsequent balancing tasks. It provides ISO 1940-compliant normalized balancing, automatic suggestions for trial weights, and detailed reports in PDF, DOC, and HTML formats. Proximity probes enhance precision for low-speed machinery, while advanced cross-correlation algorithms ensure optimal phase stability, minimizing risks like wear, increased costs, and safety hazards.

Balance

Achieve high-precision balancing in a single shot without trim runs. All results are shown in real-time, with live vectors and easy access to vibration and phase values.

Latest Updates

Initial Run Reporting for Condition Assessment

Generates detailed reports based solely on the initial run, enabling users to assess machine condition and determine the necessity of a full balancing procedure by analyzing vibration readings.

Automated Balancing Reports

Automatically generates detailed balancing reports in formats such as PDF, DOC, and Excel, providing a complete audit trail for compliance and maintenance documentation.

Ergonomic User Interface with Dark and Light Modes

Offers a customizable user experience with both dark and light themes. Dark mode reduces eye strain and improves focus in low light, while light mode enhances readability in bright environments. Both options ensure a modern, comfortable interface for any lighting condition.

Cart